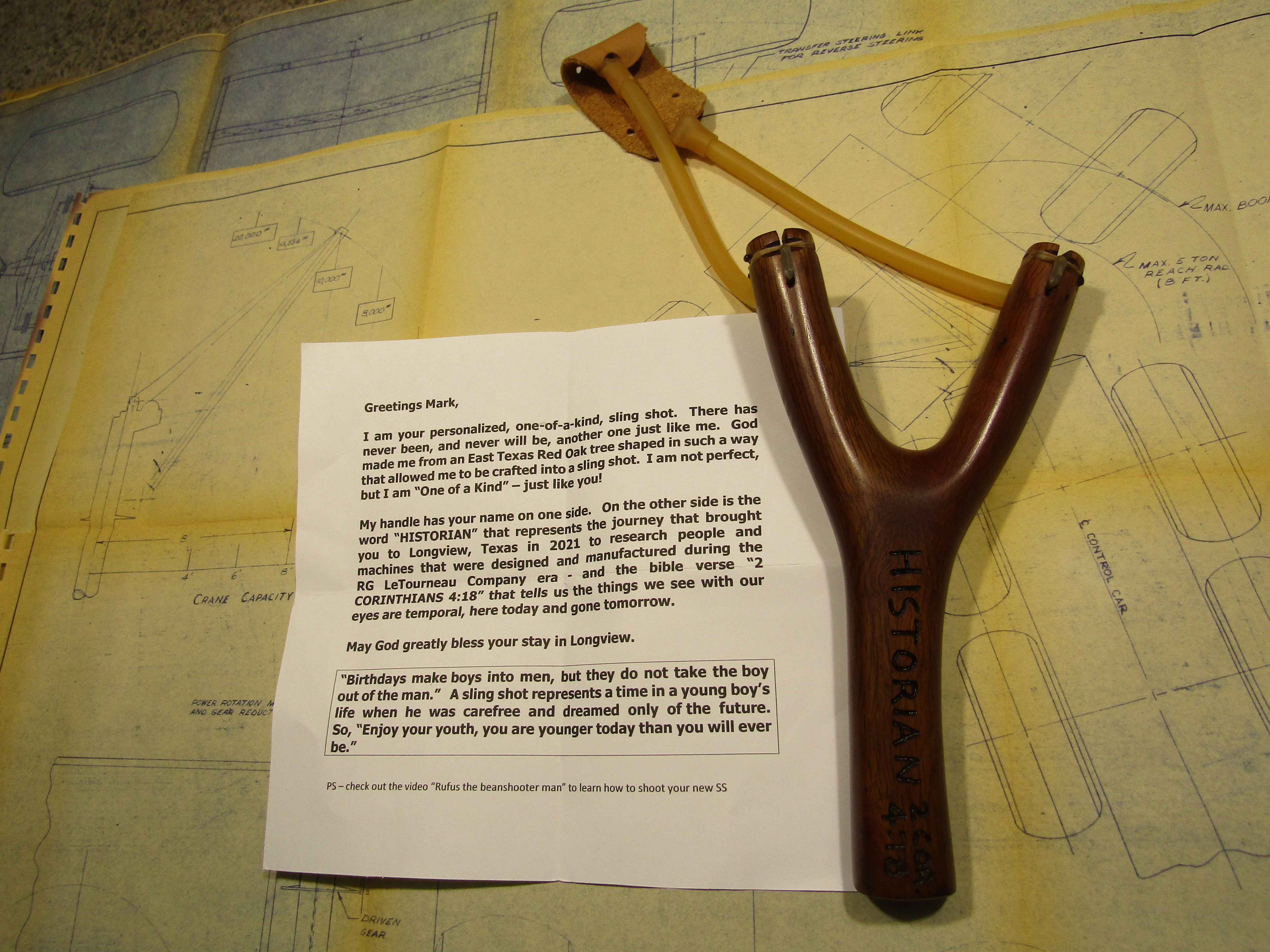

Willow Freeze was a 5 phase maneuver during the winter of 1960-1961. It involved elements from the United States Army Transportation Corps, United States Army Transportation Board Task Detachment Logistical Support, and others. The goal of Willow Freeze was to figure out logistical operations in Arctic terrain. The Sno-Train was one of many different types of logistics machinery. I will cover Willow Freeze and subsequent recovery operations in great detail within my book.

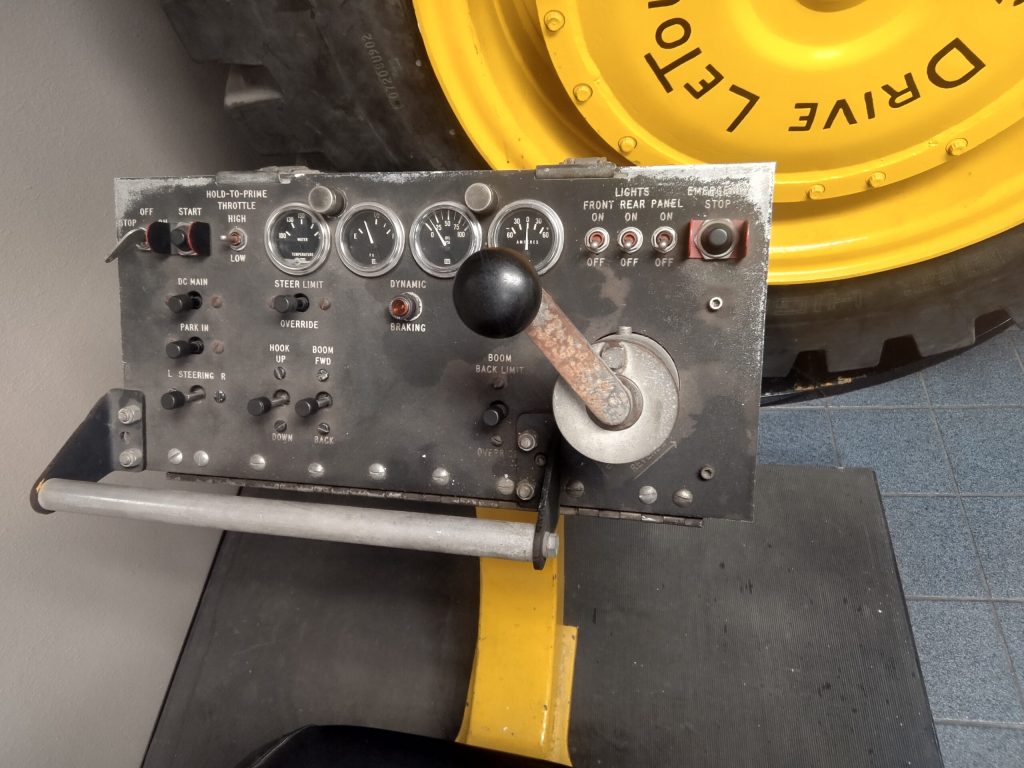

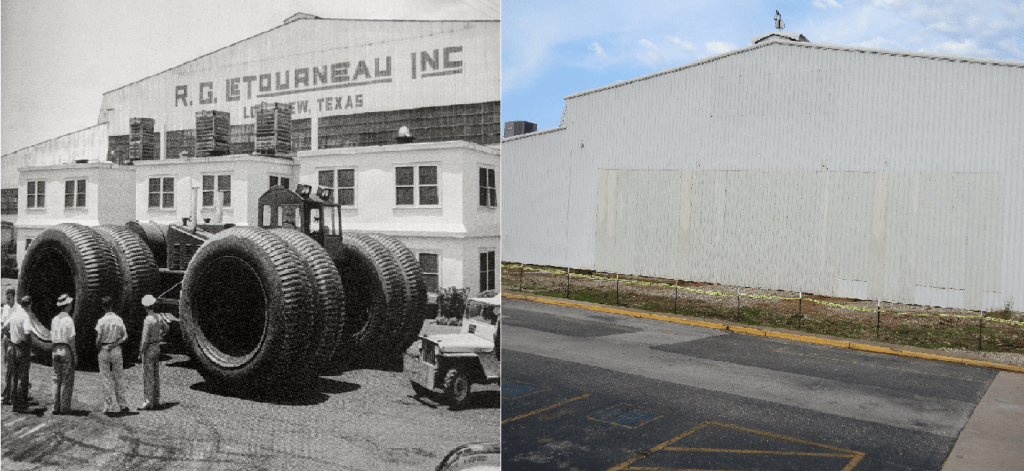

The image above shows the Sno-Train and two large wheels to the left-hand side. These wheels were the 1,000 gallon Rolling Liquid Transporters (RLT). The RLT were designed to transport fuel within the wheels. They performed well over the terrain. The Army’s only concern was that fuel could only be dispensed out of one RLT at a time.